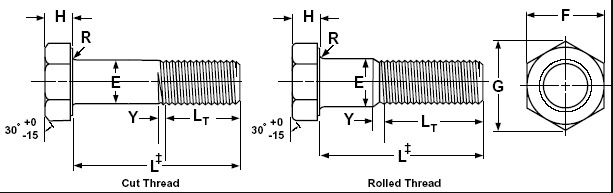

Rolled Thread vs. Cut Thread

Mechanical fasteners have either rolled thread or cut thread threads. Our customers occasionally inquire about the threading procedure, specifically which kind of bolt threading is more vital. Even though both methods produce comparable results, a few distinctions between them result in different products. Let’s discuss the differences between bolts with rolling thread and cut thread bolts before moving on to the products’ strengths.

Rolled Threaded Bolts

A set of hardened steel dies is used to cold-create threads onto a bolt during the roll threading process. The die extends into its outer diameter to create threads on the blank bolt. The steel grain flows in various directions due to the high pressure on the bolt, maintaining the structural integrity of the steel and making the bolt stronger. Due to its compression and hardening, rolled thread bolts are also easier to install and more damage-resistant.

Cut Thread Bolts

Cut threading bolts involve severing the steel’s grain structure to produce threads. While rolled thread bolts offer some advantages over cut thread bolts regarding strength and cost, cut threads can be manufactured to virtually all specifications, including larger-diameter bolts. DIC Fasteners can thread cut up to 4 inches in diameter.

Strength of Rolled and Cut Threads

Because the thread root diameter is less than the bar stock on cut or rolled thread products, it is irrelevant for evaluating tensile strength because a threaded bar breaks at its weakest point, which is in the thread root. The work that has been done in the threaded product’s weakest area is what matters. Work has yet to be done on the material in the case of a cut thread bolt. The thread is formed by removing metal. The threaded part of a rolling thread bolt is created during the cold-forming process by metal movement.

No work has been done on the material in the case of a cut thread bolt. The thread is formed by removing metal. The threaded part of a rolling thread bolt is created during the cold-forming process by metal movement. The tensile test results of the rolled threads are strengthened as a result of this procedure.

However, it’s crucial to keep in mind that heat-treated cut thread fasteners, like our 1-1/2″ A325 bolts, will function just as well as any rolled thread bolt because the heat treatment, rather than the way the bolt was formed, determines the bolt’s strength.